EV battery technology innovation promotes comprehensive electrification

Wu Kai, Chief Scientist of CATL, speaks at the 2022 China EV 100 Forum

A year ago, Robin Zeng, chairman of CATL, foretold for the first time to the industry that EV battery would usher in its TWh era in the next five years. His words might be radical and bold at that time. However, in 2021, global new energy vehicle industry witnessed a rapid development, which is beyond many people's expectations. According to the predictions of institutions including SNE Research and Bloomberg, the TWh era will indeed unfold by 2025.

Users' Pain Points Under a High Electrification Rate

In 2021, the three major markets in the world have seen their electrification rates accelerated across the board. As new energy vehicles have been accepted by thousands of families to record an increasing penetration rate, users develop greater anxiety and complaints about different shortcomings of new energy vehicles, including those on range, safety, charging, range loss in winter, and low residual value. It is the responsibility of the entire industry chain to solve these core pain points of users, and battery companies in particular shall shoulder more responsibilities.

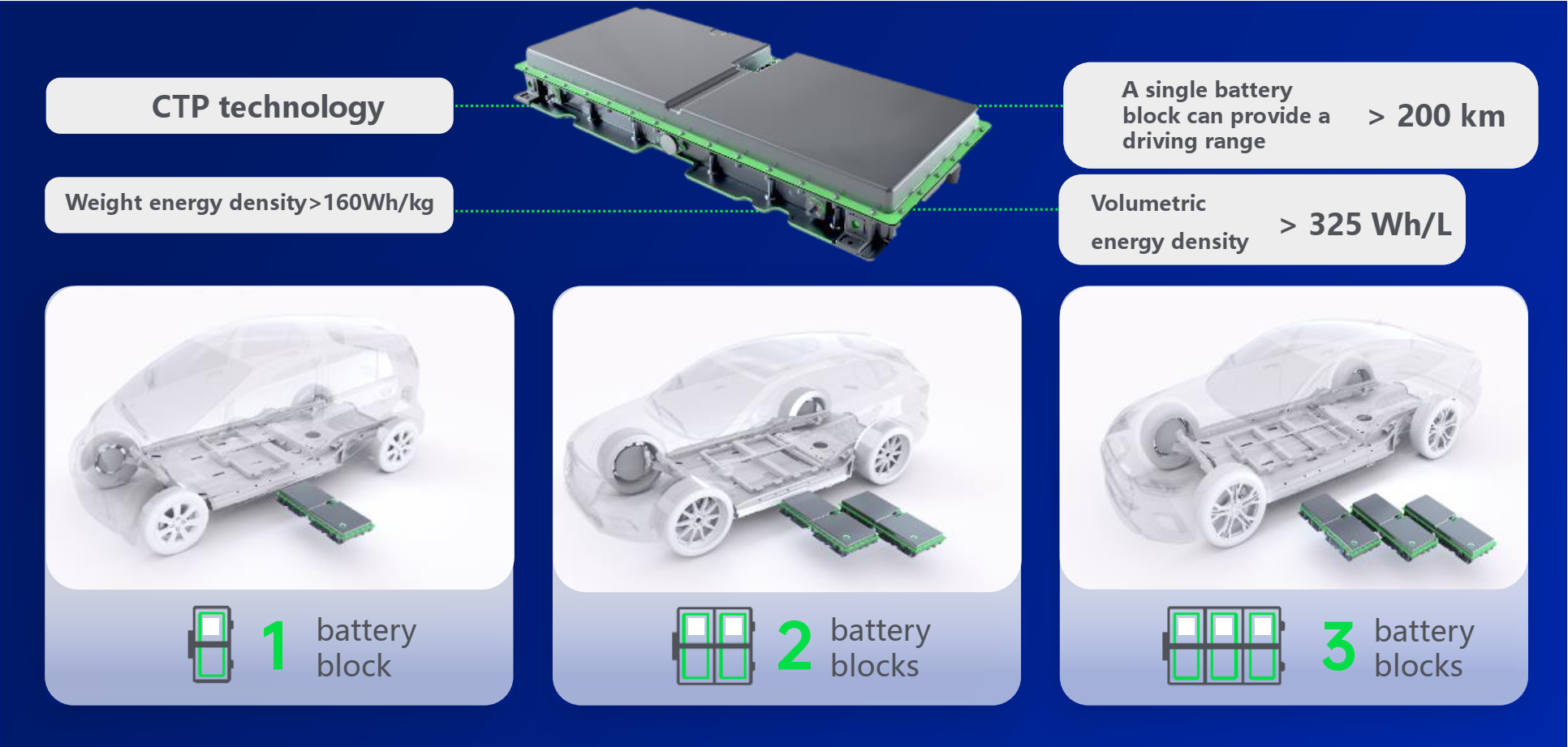

Facing up to these challenges, CATL solves the problem of users' anxiety and facilitates the process of comprehensive electrification through our technological highlights such as Cell to Pack (CTP), No Thermal Propagation, and EVOGO battery swap solution.

Technological Innovation Drives Electrification

01 Cell to Pack (CTP)

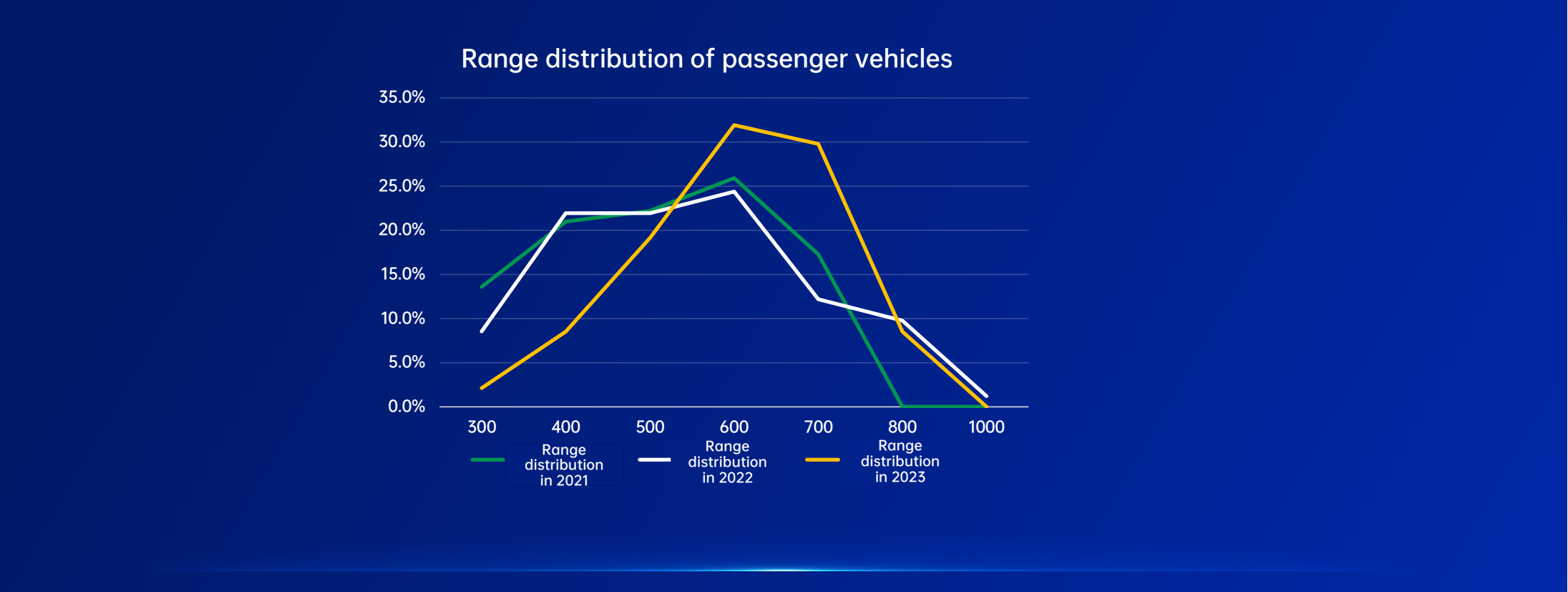

As shown in the figure below, we have analyzed the range distribution of passenger vehicles of the past three years. It is still a trend for consumers to seek for a long range. In this era of comprehensive marketization, however, we have to find a balance between long range and economical efficiency. In addition to solving the problem of range anxiety, CTP is also able to achieve cost-effectiveness by combining different chemical systems.

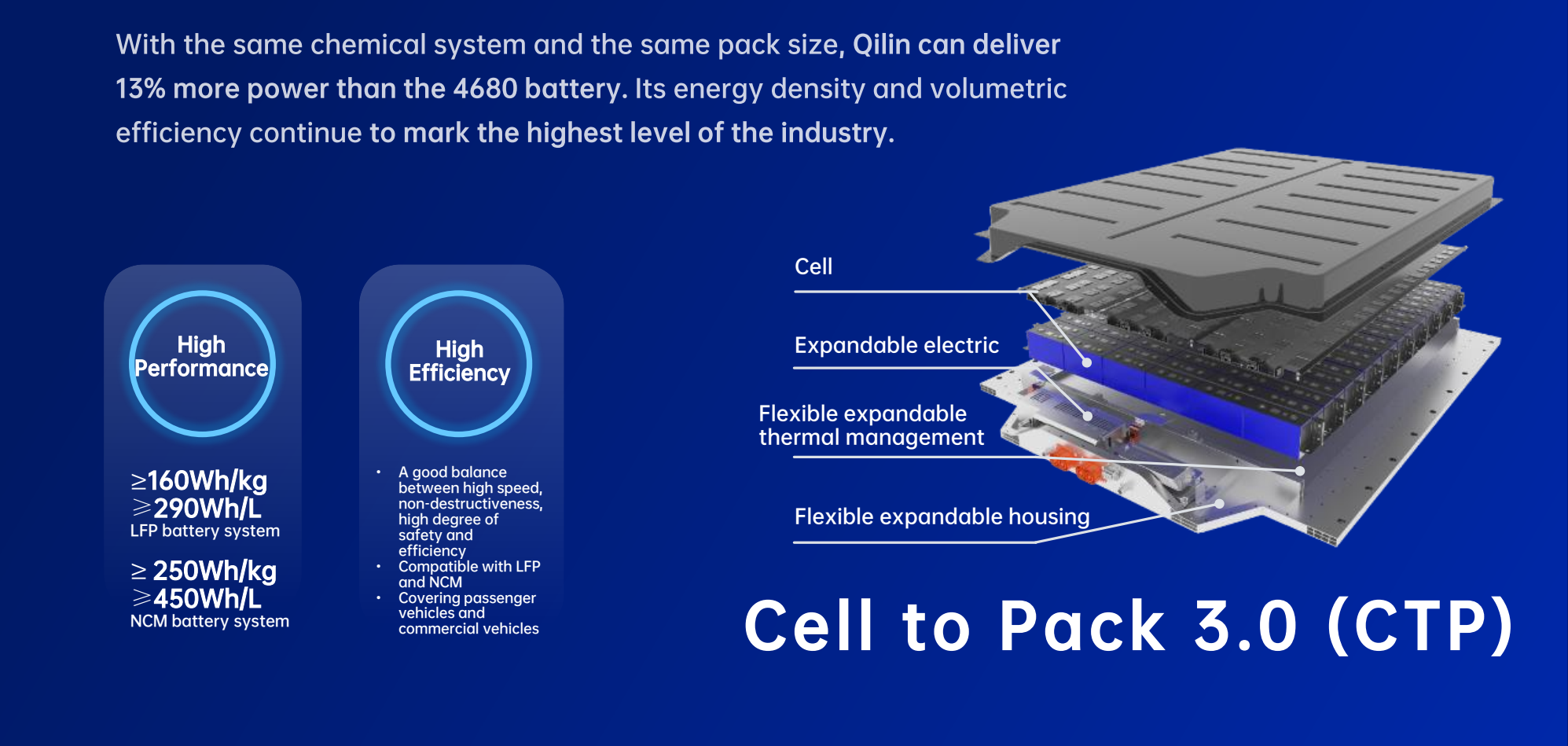

Through continuous technological iteration, CATL has launched the third-generation CTP, which is called Qilin Battery internally. Its system weight, energy density and volumetric energy density continue to stay at the highest level of the industry. With the same chemical system and the same pack size, Qilin can deliver 13% more power than the 4680 battery.

02 No Thermal Propagation

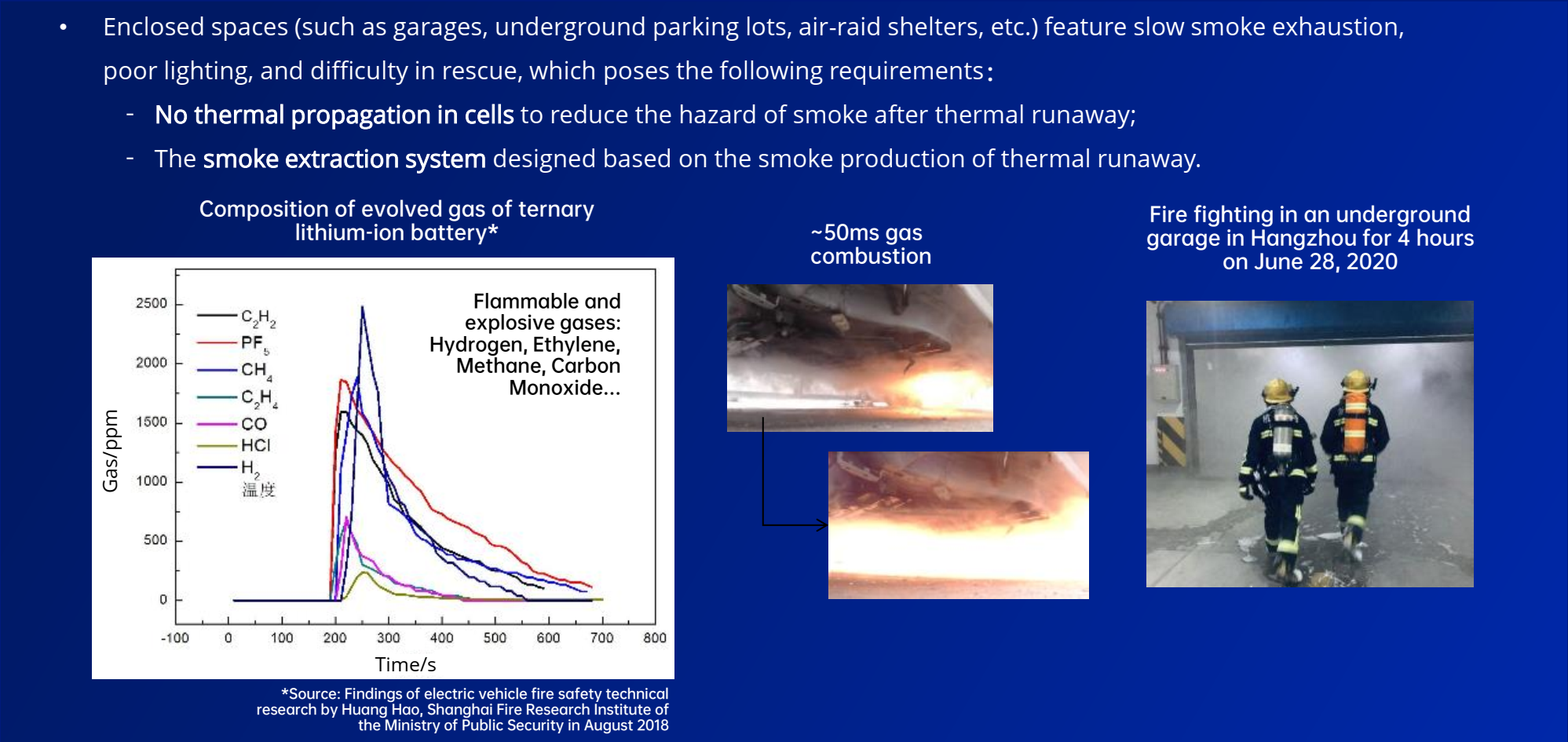

Aiming at the safety of new energy vehicles - more and more enclosed spaces are emerging in our lives now, such as garages, underground parking lots, air-raid shelters, etc. These enclosed spaces feature slow smoke exhaustion, poor lighting, and difficulty in rescue, which poses higher requirements for the safety of battery systems.

If no thermal propagation happens to the system on any single cell failure, the smoke hazard resulting from thermal runaway can be greatly reduced. It is easy to design and install the smoke extraction system based on the smoke production from thermal runaway of single cells in a building. In this way, the safety of new energy vehicles can be greatly improved, thus to protect life and property to the greatest extent.

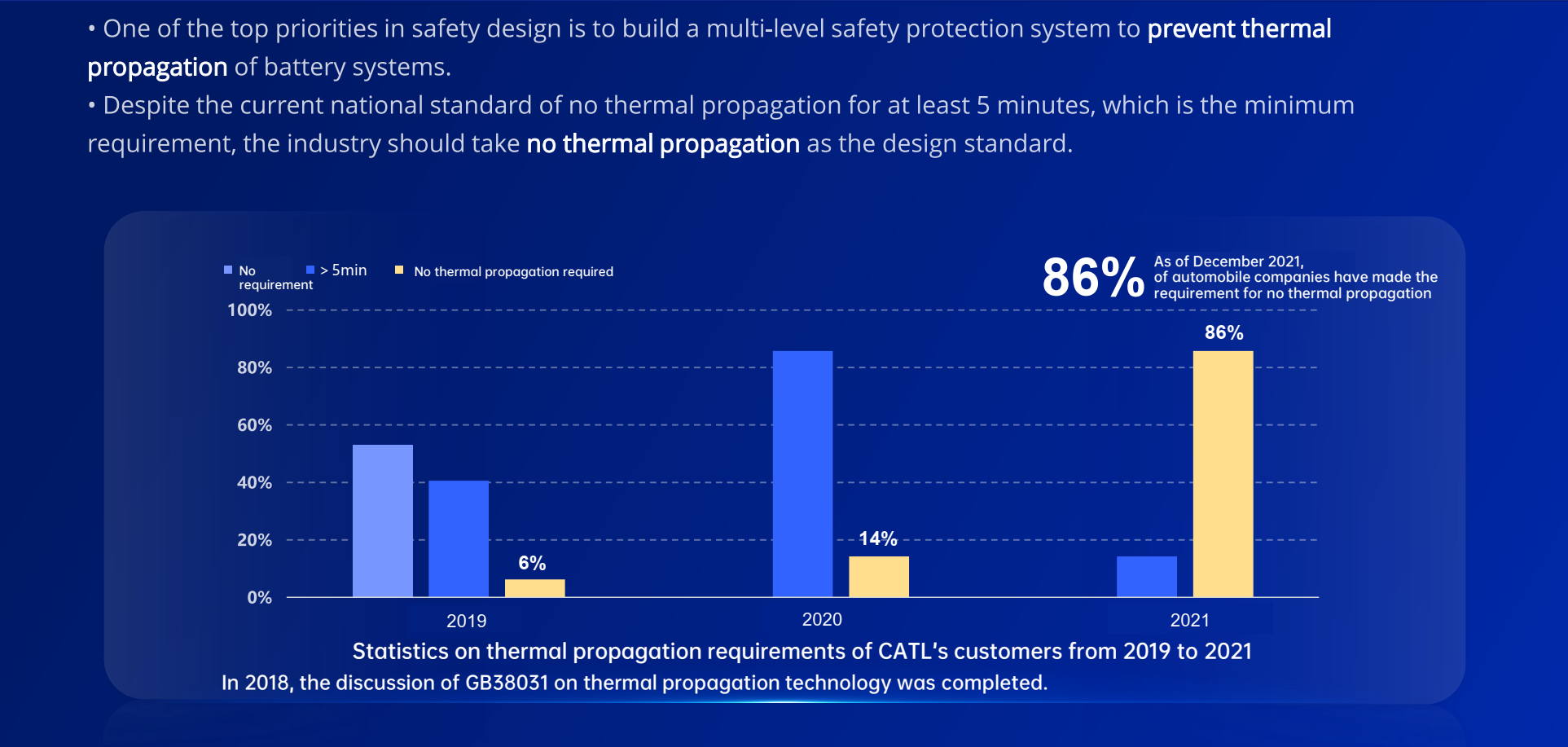

Despite the current national standard of no thermal propagation for at least 5 minutes, which is the lowest requirement, companies should take no thermal propagation as their design standard. In fact, advanced companies have taken the initiative to achieve the goal of no thermal propagation of battery systems by building multi-level security protection technology.

The figure below shows the statistics of automobile companies' requirements for thermal propagation of our products in the past three years, representing a trend of continuous improvement.

Statistics show that in 2019, half of the customers had no requirements for thermal propagation; in 2020, more than 80% of the customers wanted the same requirements with the national standard, that is, there should be no thermal propagation for at least 5 minutes, and 14% of the customers required no thermal propagation of the system; in 2021, the safety requirement of the customers have been completely changed, for 86% of them required no thermal propagation of battery pack. CATL’s customers basically cover the vast majority of automobile companies at home and abroad, which means that no thermal propagation has become a common requirement of automobile companies for the safety of battery systems.

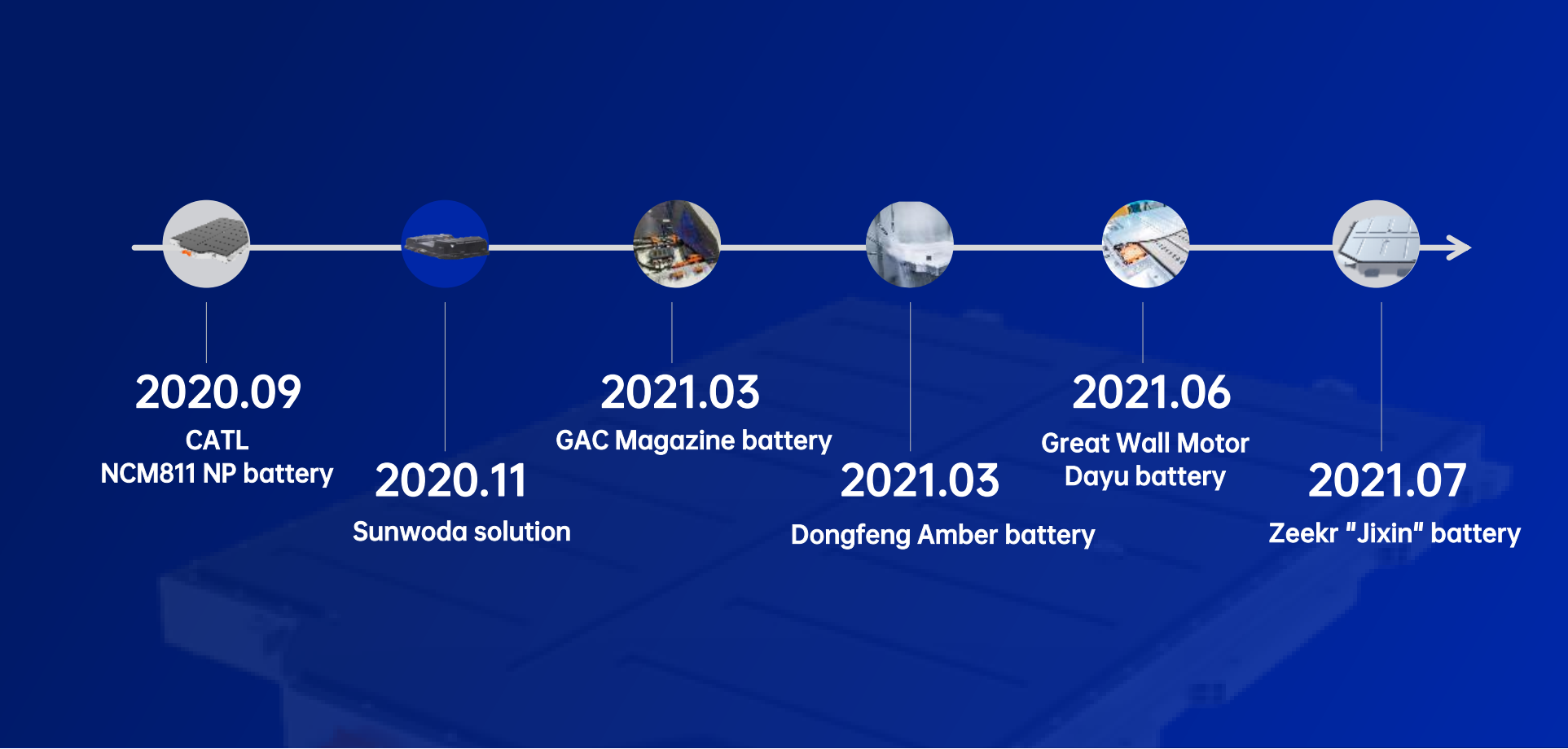

In September 2020, CATL took the lead in realizing no thermal propagation on 811 products. Some automobile and battery companies also followed suit to launch their own no thermal propagation technology. The technology has become the mainstream of the industry.

CATL has been committed to the safety design of high energy density systems. Following the mass production of the 8-series products featuring no thermal propagation in 2020, the no thermal propagation technology with a higher energy density of 1,000 km will also be mass-produced in 2023.

03 EVOGO battery swap solution

To relieve the consumers' anxiety about cost, charging and residual value and to meet the application needs of multiple scenarios, we have launched EVOGO battery swap solution:

• For end users: The separation of vehicle and battery reduces the initial purchase cost of electric vehicles; the number of battery packs can be selected according to actual needs, which is more economical.

• For automobile companies: Their products can be adapted to the standard battery block, so that they don't need to invest in or build their own battery swapping station, and share the same battery swapping network instead.

• For battery swapping operators: The battery swapping station is compatible with different vehicle classes, brands and models, which further ensures an outstanding economical efficiency.

• For social resources: The infrastructure is shared, to avoid repeated investment of social resources, such as land, electricity, etc., and avoid the problem of insufficient utilization.

Together for the comprehensive electrification

To sum up, I would like to say that electrification has ushered in a new era. I hope that everyone can work together to keep improving the user experience with new technologies, new breakthroughs and new standards. Let’s work together for the advent of comprehensive electrification.

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link. Read More