Robin Zeng: Innovation Drives the TWh Era

Speech by Dr. Robin Zeng at the 2022 World EV&ES Battery Conference

Innovation is the core competitiveness of CATL. My speech today is mainly composed of three parts: first, a brief review of the development of e-mobility in the past ten years; second, the opportunities and challenges we are facing; finally, how to make innovation happen.

01

Innovation brings qualitative change for the development of e-mobility in the past ten years

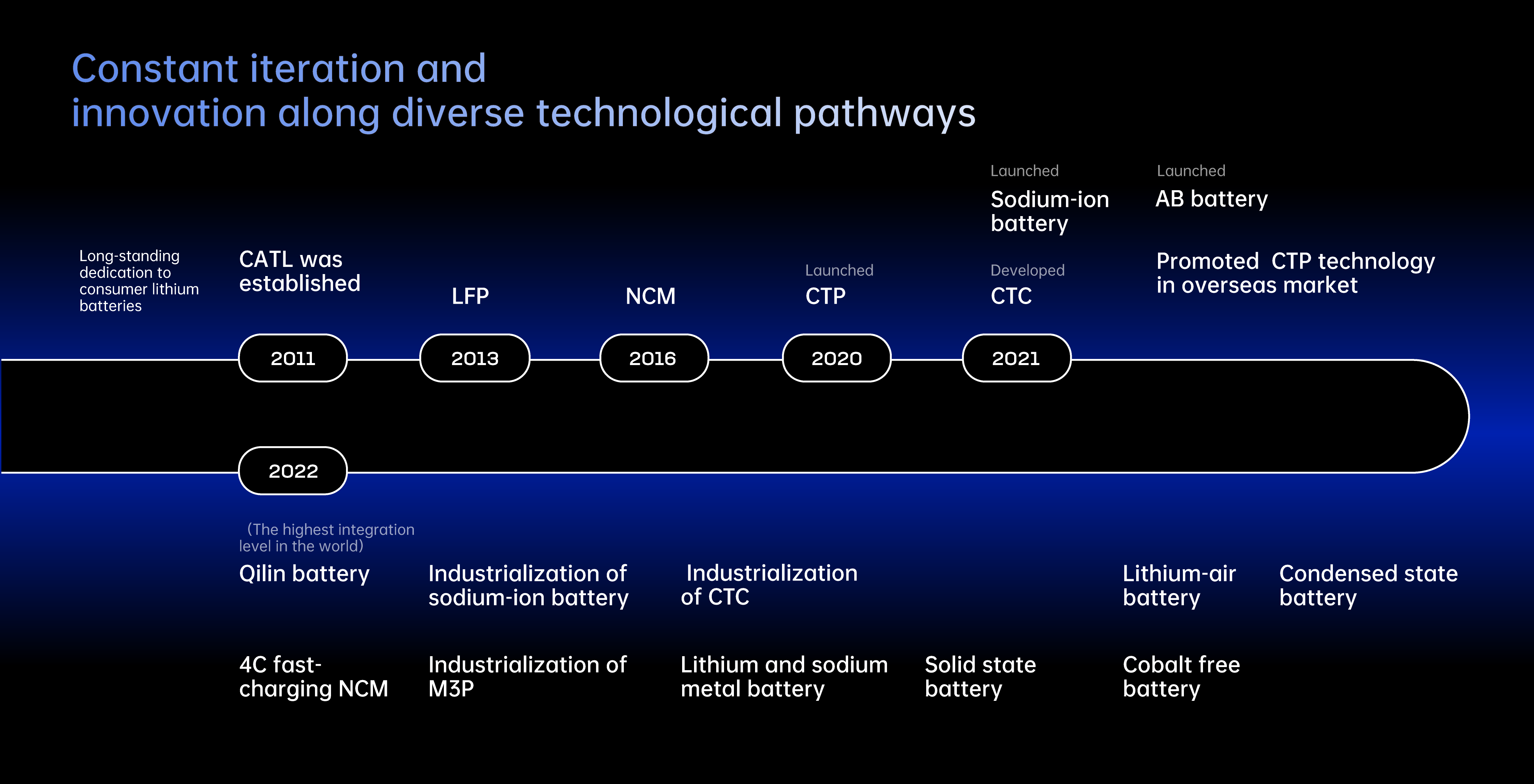

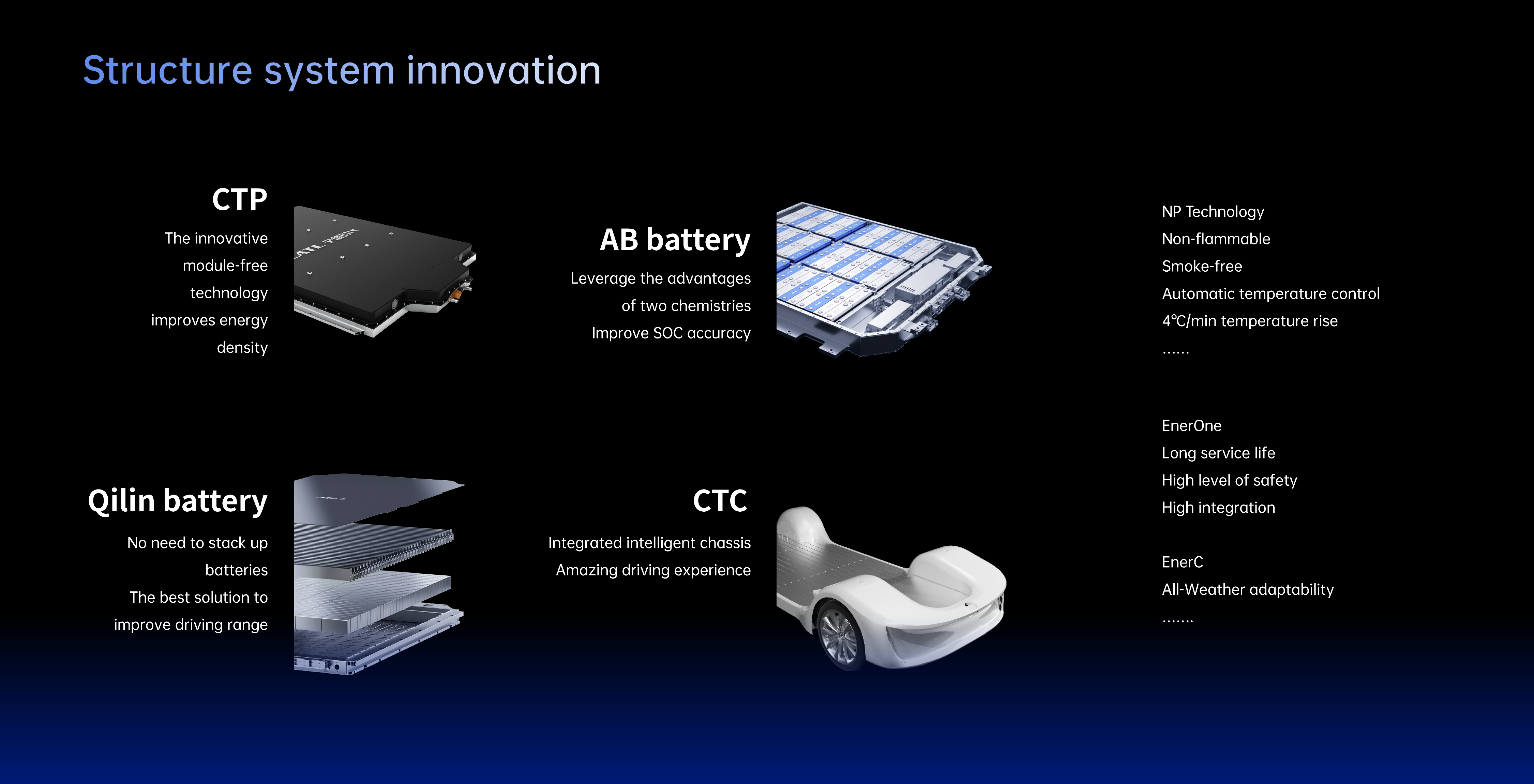

This shows the technological milestones of CATL. In the past ten years, in terms of material and electrochemistry innovation, we were the first to achieve mass production of NCM 811 batteries in the world. In terms of structure system innovation, we were the first to release and mass produce module-free CTP technology, which has paved the way for structure innovation, as multiple players in the industry followed suit and developed new products based on this creative idea. CATL now boasts the world’s most comprehensive battery technology capabilities and the fastest transfer of technology from the lab to the market.

Through continuous innovation, the increase of energy density of EV batteries has brought about a six to seven times increase in driving range and an 80% reduction in costs over the past 10 years. However, the recent price surge of raw materials has driven up the cost again.

As for the application scenarios of our products, our batteries can be applied on land, in the sea and in the sky. You can find our batteries in the Everest base camp at an altitude of 5,000 meters as well as on the Yangtze Three Gorges-1, the world's largest pure electric commercial vessel.

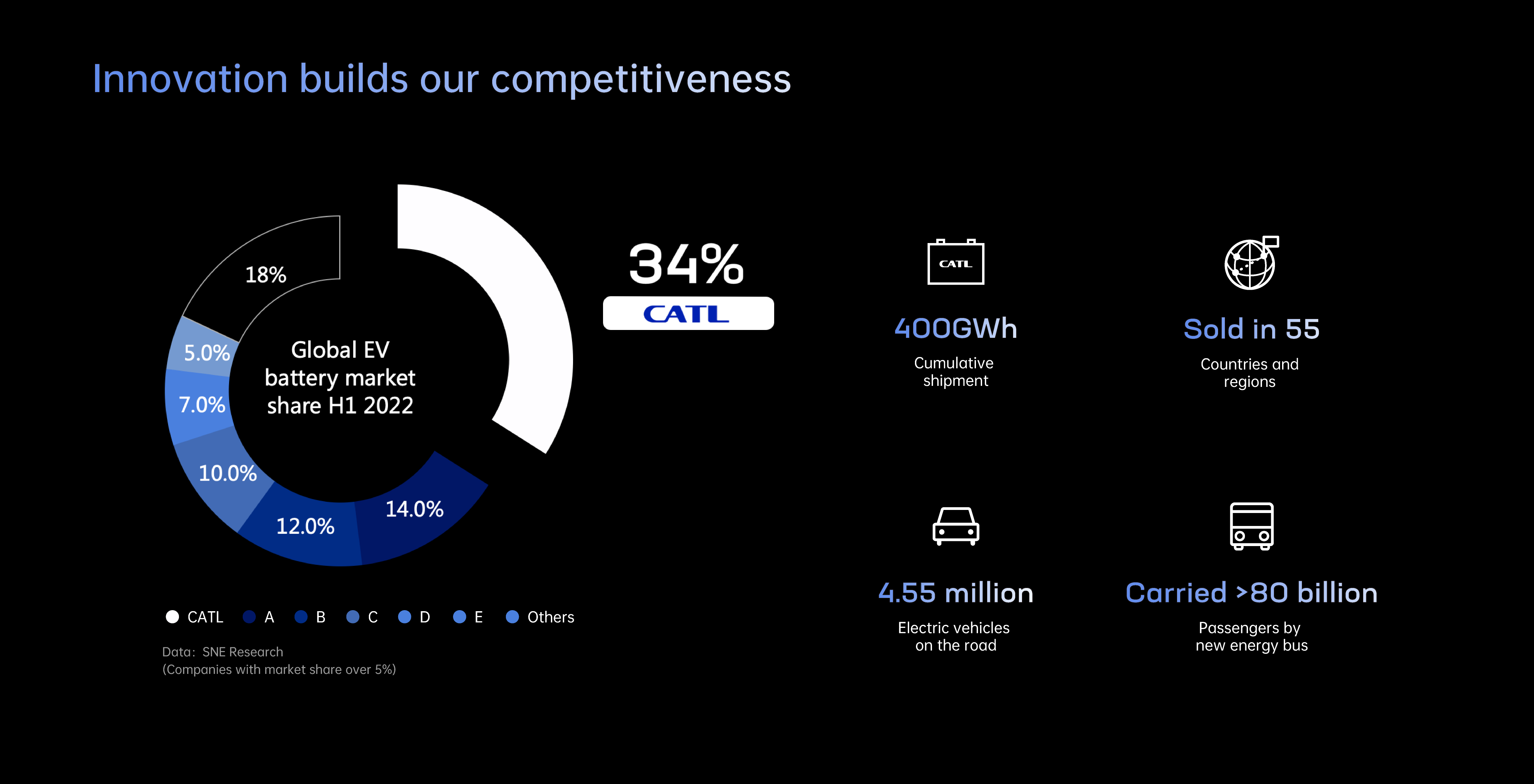

We believe innovation is the core competitiveness of CATL, and it has won us wide recognition from customers. Our market share in Europe is growing rapidly. According to the latest data from SNE Research, CATL's global market share reached 34% in the first half of this year. CATL's products now covers 55 countries and regions around the world, and the total shipment of EV batteries has exceeded 400GWh, which means one out of every three electric vehicles in the world is equipped with CATL’s batteries, allowing us to contribute more wisdom and strength to the global e-mobility.

02

Opportunities and challenges in the TWh era

With the acceleration of comprehensive electrification, we will soon enter the era of TWh.

The industrial opportunities are easily accessible. The penetration rate of new energy vehicles in China has remained above 25% in the past four months. According to BNEF data, the electrification rate of passenger vehicles under net-zero scenarios will reach 62% by 2030. The demand for energy storage, according to the prediction of GGLB, will also exceed 1TWh in 2030.

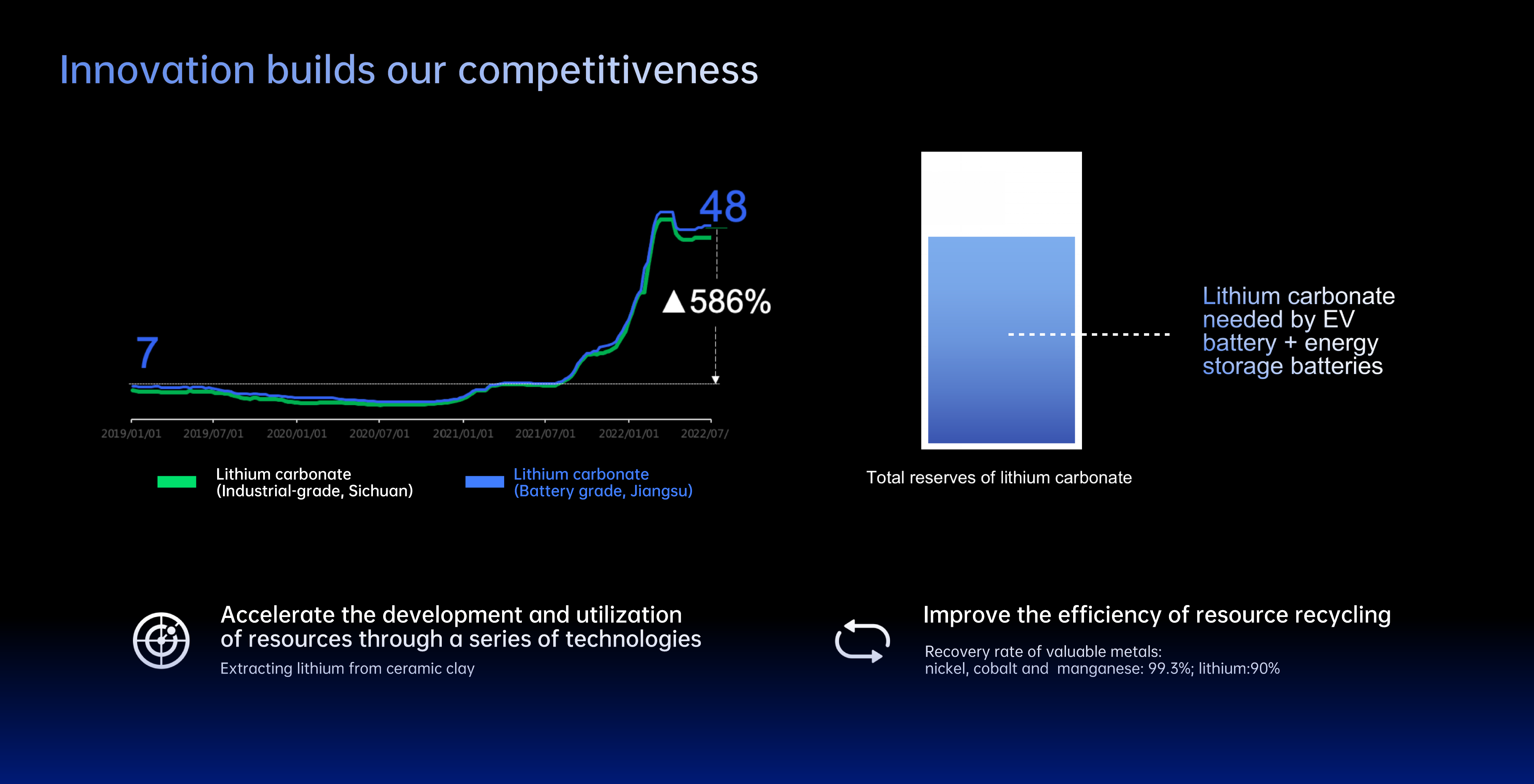

In such case, the speculation on raw materials has posed short-term challenges to the industry chain, as the past year has seen the price surge of raw materials such as lithium carbonate, PVDF and lithium hexafluorophosphate. However, in fact, mineral resources are not the bottleneck for industrial development. First of all, the proven reserves of lithium can produce 160TWh of lithium batteries, which are fully sufficient to produce the EV batteries and energy storage batteries needed worldwide. Secondly, we will improve the development and utilization of China’s superior mineral resources through a series of technologies such as extracting lithium from ceramic clay. Finally, unlike oil, which is unrecyclable, most of the materials in the battery can be recycled and reused. At present, the recovery rate of nickel, cobalt and manganese has reached 99.3% in our recycling plants, while that of lithium has reached over 90%. After 2035, recycling the materials in retired EV batteries by CATL can meet a large part of the market demand.

So, what are the real challenges that the industry chain and enterprises face? First, consumers requires stronger R&D capabilities; second, large-scale delivery needs a higher level of manufacturing capabilities; and third, further development of the industry calls for better service capacity.

03

Embrace changes through innovation

Innovation has enabled us to become the leader of the industry, and it will help ensure our continued success in the fast-paced TWh era.

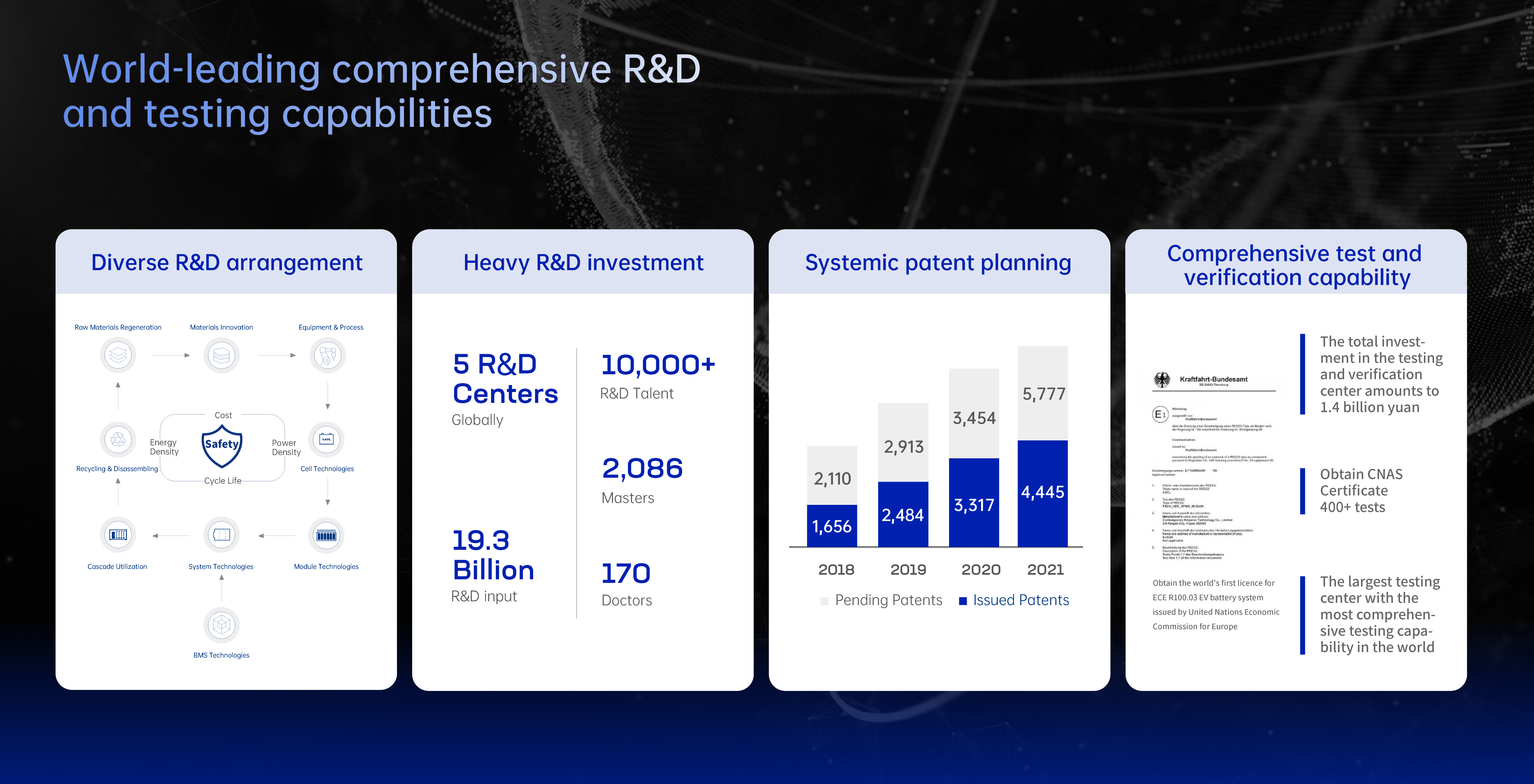

Every year, we invest 6-7% of our revenue in R&D, and in 2021 our R&D investment amounted to 7.7 billion yuan (about 1.21 billion U.S. dollars). We have a world-leading R&D team of more than 10,000 people, and has built the world’s largest and the most comprehensive testing and verification center.

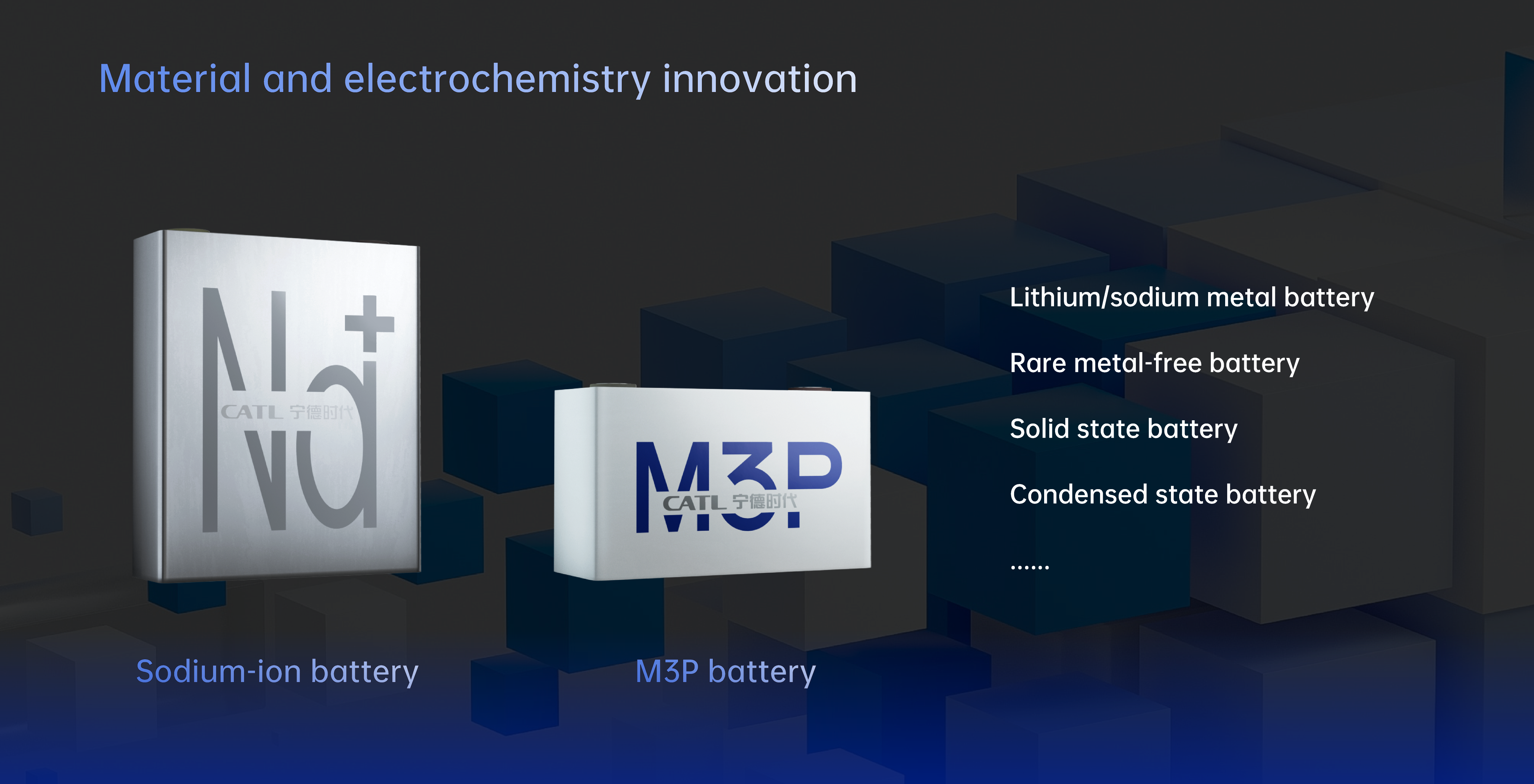

The innovation of material system is crucial to the improvement of battery performance. With the computing power of one quadrillion times per second, we have leveraged advanced algorithms based on the First Principle, so as to identify the joint points between various chemical elements and the best balance of the cathode, anode, electrolyte and separators. On the other hand, we can provide positive feedback on product research and development and develop various solutions by analyzing the real on-board data. Since the computing power, algorithm and data are complementary to each other and build up a complete closed loop, we are able to make breakthroughs in sodium-ion batteries, M3P and other materials.

In terms of structure innovation, we have recently launched the CTP 3.0 technology, or Qilin battery, which marks the highest integration level of battery systems in the world. It can easily reach a mileage of 1,000 kilometers without stacking up batteries. Next year, several new models equipped with Qilin battery will be launched on the market.

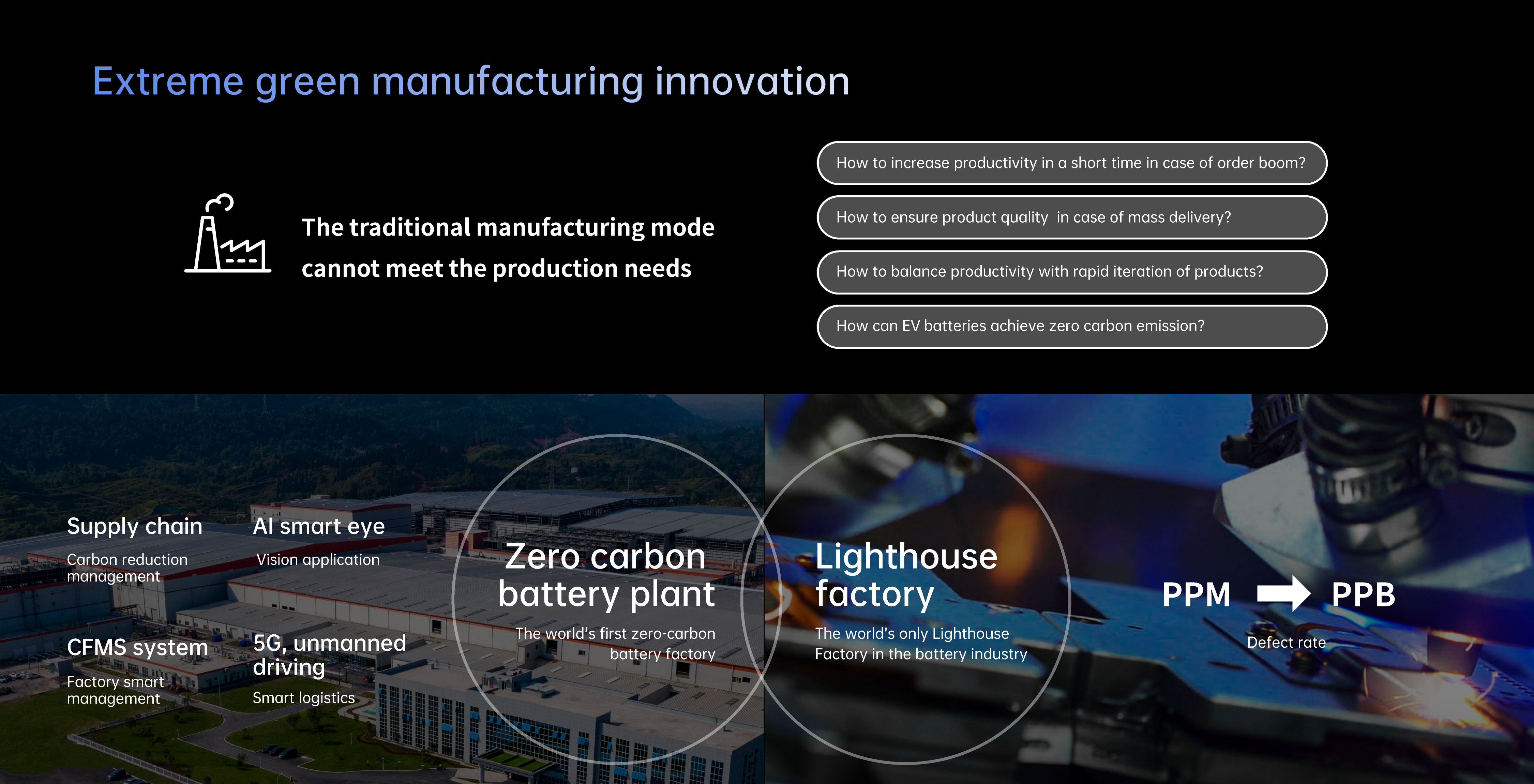

Extreme green manufacturing innovation is what Industry 4.0 requires of us. CATL’s Ningde base was selected as one of the Lighthouse Factories by the World Economic Forum last year, becoming the first and only global Lighthouse Factory in the battery industry. We have made revolutionary innovations in manufacturing system, production line layout, key process optimization and digitalization, reducing the defect rate to PPB level. Through a series of independent R&D and innovation, our Yibin base achieved carbon neutrality in 2021, becoming the world’s first battery factory with the PAS2060 Certificate issued by SGS. In addition, we have examined the carbon footprint of the supply chain and provided guidance to enterprises across the supply chain in the hope that consumers will enjoy the benefits of our zero carbon batteries at an early date.

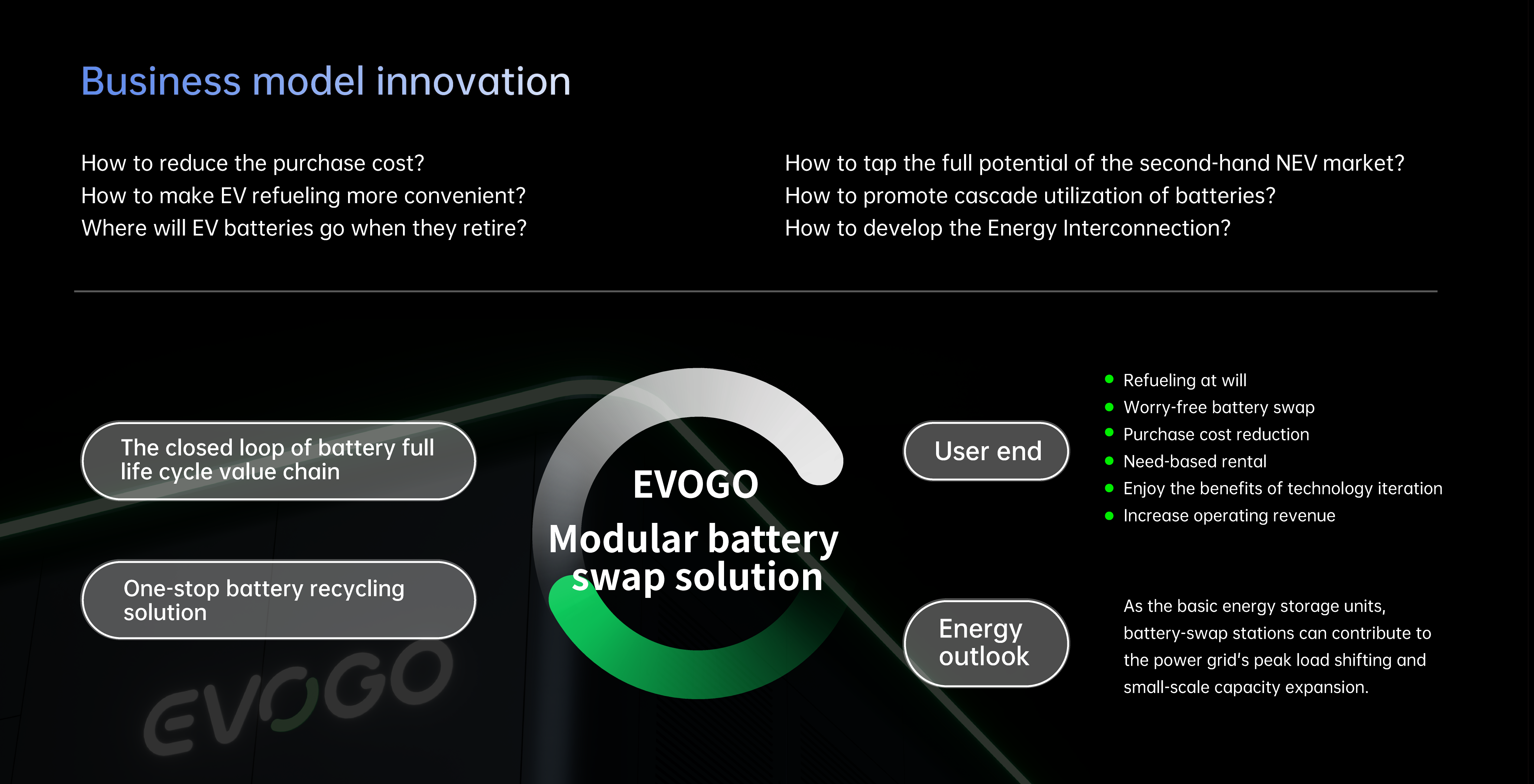

Finally, it is urgently needed to leverage innovation in business model to connect the links of production, application, and recycling. EVOGO, our battery swap solution, has been put into service in Xiamen and Hefei this year, and with our innovative modular battery swapping solution, we have improved the market penetration of affordable cars. We are also in the middle of co-developing more battery swap EV models, which will be launched in more cities.

CATL is willing to work with all parties to seek win-win results, producing better results out of the innovation-driven TWh era.

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link. Read More