CATL secures its fourth zero-carbon factory

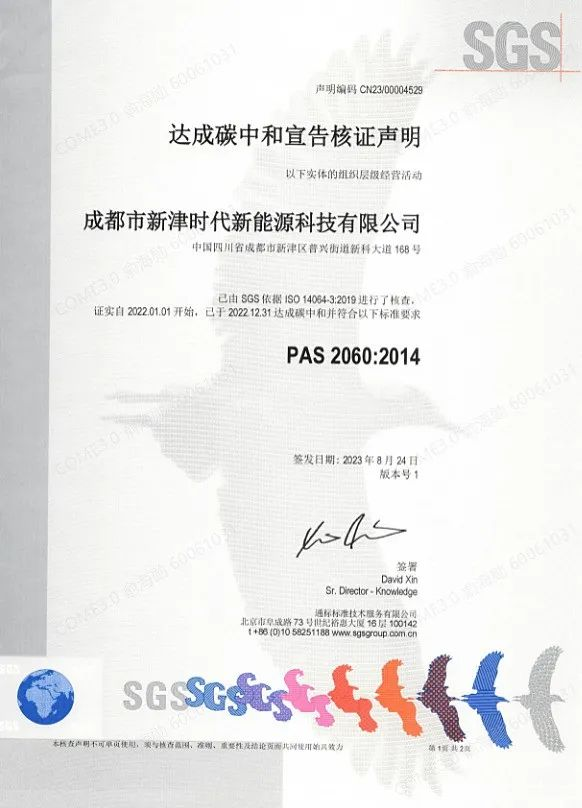

PAS2060 carbon neutrality certificate issued by SGS to CATL-XJ

Recently, Chengdu Xinjin Contemporary Amperex Technology Limited (CATL-XJ), a wholly-owned subsidiary of CATL, received the PAS2060 carbon neutrality certificate issued by the certification body SGS, making it the fourth zero-carbon factory of CATL.

With CATL-XJ being certificated as a zero-carbon factory, CATL takes a step closer to its strategic goal of achieving carbon neutrality in core operations by 2025 and throughout the value chain by 2035.

Located in Chengdu, Sichuan, CATL-XJ started mass production in July 2021. Since its establishment, the plant has been actively committed to China’s carbon peaking and carbon neutrality goals, and carved out a clear path for energy conservation and emission reduction. Besides, it has been continuously involved in transformation and innovation in energy utilization, transportation and logistics, production and manufacturing, making every effort to reduce carbon emissions.

![]()

Production Base of CATL-XJ

The extensive and in-depth application of digital technology throughout the entire factory carbon emission reduction chain is one of the core measures taken by the plant. It has developed a CFMS smart factory management system to provide an intelligent control system for green energy systems, detect equipment status in real time, and collaboratively optimize the total energy consumption of the system and the status of each sub-equipment, ensuring energy security and stability.

In terms of green manufacturing, CATL’s Chengdu plant has built a central control management system for digital production, as the global visual management can significantly reduce process losses. The AI visual detection system can automatically learn and extract defect characteristics, and improve detection rate in various tasks such as slitting and winding.

At the same time, the plant is electrifying the logistics chain and making extensive use of electric transportation to achieve zero-carbon operation from the supply chain to production and then to the user end. In terms of energy use, CATL-XJ adopts 100% renewable hydropower, providing clean energy for production and manufacturing.

In March 2022, Yibin plant became the world’s first zero-carbon battery factory. As of now, CATL has four zero-carbon factories, with the number and pace of zero-carbon factory certification staying well ahead in the new energy industry.

Under the guidance of the national carbon peaking and carbon neutrality commitment, CATL takes the carbon neutrality strategy as the guiding principle, and technological innovation and smart management as the driving force to continuously drive the systematic carbon reduction of the industry, striving to inject green momentum to the zero-carbon upgrading and the high-quality development of the industry.

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website. Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link. Read More